The Client

The client is one of the leading food retail, wholesale and distribution companies. Currently headquartered in West Midlands, it started its operations in 1917 as a counter-service grocery store, has built an 8,000 strong workforces spread over 300 different locations. With a turnover of around £1 billion and it is the largest SPAR distribution center in the UK, owning 280 SPAR stores and serving 1,000 in total across England and Wales.

The Challenges

The leader in the wholesale industry desired an integrated system to synchronize supply and demand managing products and end-customers along with smooth functioning of the wholesale business cycle including planning, order management, inventory management, distribution and payment transaction.

The warehouse management system was an independent system functioning in the silo. Thus, information gathering across the organization, while validating from other systems, was time-consuming and at the same time lacked accuracy. The system needed immediate integration with other applications such as invoices, products/services and delivery management; making it flexible and accurate with firmed-up data.

A solutions partner with strong expertise and experience in end-to-end application development and support was desired; in line with the industry’s best practices and tools to cater to Demand-Supply Integration (DSI) resulting in improved organization’s performance.

The Objective

The client witnessed managing a large quantity of items and high volume of inventory across its 1300+ convenience stores in the UK and Wales through its proprietary Warehouse Management System – “Multi-Depot System”. The home-grown system was responsible for seamless functioning of warehouse operations including inventory management, assembly management, quality and compliance, storage of goods and timely dispatch of orders. The client required a robust and efficient solution to manage their ever-growing warehouse operations along with integration with third-party systems in finance, point-of-sale and retail departments.

The Solution

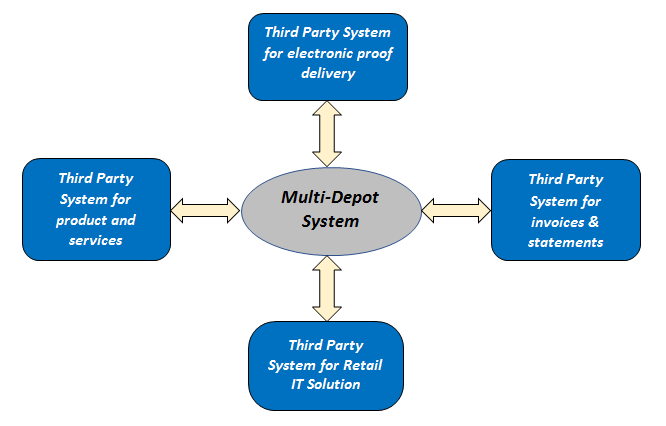

JK Tech, as the client’s solutions partner played a pivotal role in technological evolution and advancement for their warehouse management system while integrating the Multi-Depot System with other third-party applications such as:

- Application for invoices and statements to be delivered instantly and on-line, on-demand access for end customers.

- Application for electronic Proof of Delivery (ePOD) system for managing deliveries and collections enables customer delight while facilitating accurate and timely delivery.

- Application for product and prices.

- Claim Management System with electronic proof of the delivery system.

- Application for end-to-end retail IT Solution.

Figure 1: Integration of MDS with Other Systems

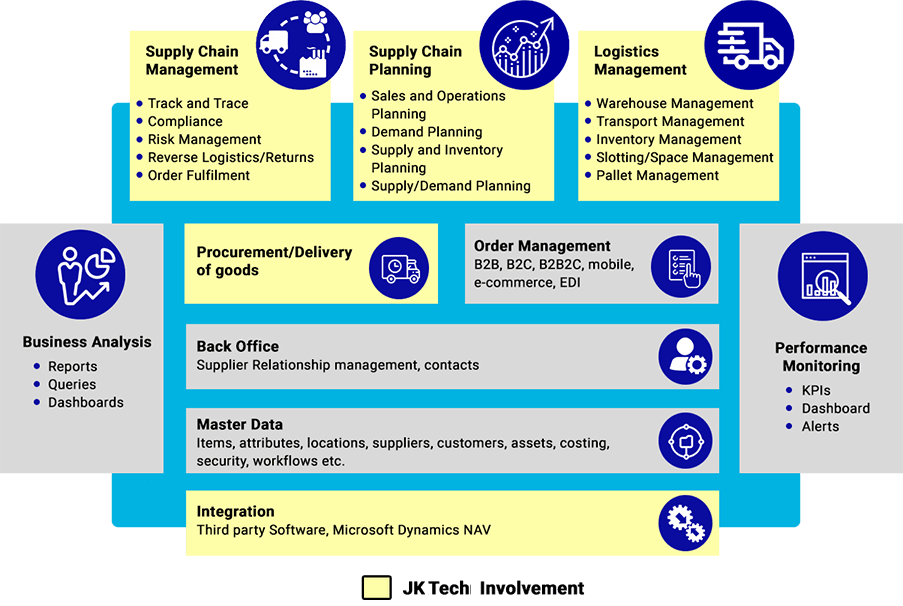

The solution developed in Progress 4GL using GUI, REST Services (Progress Based), SQL and SSIS (Integration tool) resulted in flexible, robust and accurate warehouse operations allowing integrated and smooth information flow. The fully integrated solution provided higher visibility on inventory across multiple locations with centralized operations through a single interface.

Figure 2: JK Tech MDS Solution Footprint

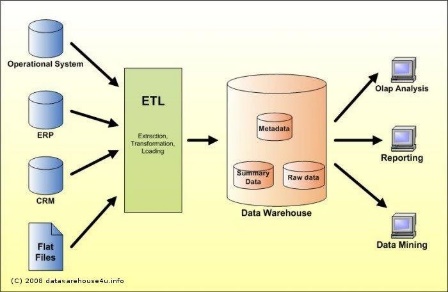

Data Warehouse Design and Implementation

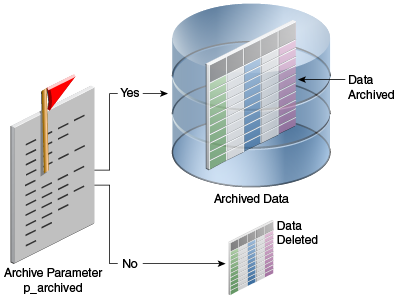

Data Warehouse was designed implemented and integrated using the SQL Server integration services tool. The Microsoft SQL server scripts were developed using Microsoft best practices to archive & classify 2.5 TB legacy data, design the workflow and standardize the documents, thus managing, optimizing and monitoring their data warehouse end-to-end.

In addition to that, the components developed by our team were reusable, generic and flexible.

Figure 3: JK Tech Footprint – ETL & Data Warehouse

Figure 4: JK Tech Footprint – Archived the Legacy Data

The application developed also ensured accuracy of all warehouse processes starting from receiving goods followed by tracking inventory, slotting for efficiency, document preparation picking and shipping, customer service, tracking/visibility and reporting. The solution encompassed shipping and receiving processes and integrated with other systems in the supply chain process to ensure enterprise-wide data transparency. It not only controlled but also tracked the transfer and storage of materials in the warehouse resulting in a dynamic warehouse management system.

Supported Modules

- Order Routing

- Inventory Management

- Logistics Integration

- Return Management

- Reporting

- Monitoring the backups & integration jobs

Our Technological Expertise

- Progress 4GL

- OpenEdge GUI

- REST Services (Progress Based)

- Microsoft SQL

- SSIS (Integration tool)

- IDERA- SQL Diagnostic Manager

The Benefits

- The integration of multi-depot systems with third-party systems and applications resulted in 30-40% of cost reduction.

- The updates made in the application enhanced the performance up to 50-60%.

- Reduced effort on rework and efficient system applications resulted in time savings of up to approx. 50% and increased efficacy of the system by 40%.

- Legacy data of approx. 2.5 TB was archived and was classified year-wise for 10 years resulting in faster and easy access to data.

- The solution integrated with the third-party systems and applications resulted in stock control, optimized warehouse space, order accuracy and many more that an organization struggled in day-to-day operation in the warehouse.

- Increased customer delight for the client’s end-customers was achieved through improved inventory accuracy, improved flexibility and responsiveness of the application.