The Client

The client is a leading global manufacturer of alcoholic beverages with more than 200 brands that are sold in 180 nations.

The Challenges

The major challenges faced by the client were:

- The client’s export warehouse was running on hardware and software that is outdated and no longer supported, representing a major operation and cyber security risk.

- The client exported over £40m p.a. out of their warehouse across regions and was operating at risk.

- The current system solution (deployed 1995) was operating at a seriously high-risk level.

- In the event of Hardware Failure (Server) the particular hardware is no longer available & as a result, it would not be possible to set up the Oracle WMS system on new hardware.

The Objective

Being a well-established and leading global manufacturer of alcoholic beverages, the client desired a smooth-running warehouse for achieving the business’ productivity goals. The export warehouse was back operating the normal day-to-day activities without any business impact and the legacy Oracle Warehouse Management System (WMS) was decommissioned.

The client was looking for a new solution that could further enhance Picking list generation in SAP with instructions on batch and quantity. A solid warehouse management system was required that could help move goods through the warehouse as quickly as possible, improving each step of the fulfillment process and increasing process efficiency, consistency, and quality control.

The Solution

JK Tech’s team understood the key challenges and strategized a client-specific solution in the form of SAP Full WMS to drive their digital transformation journey.

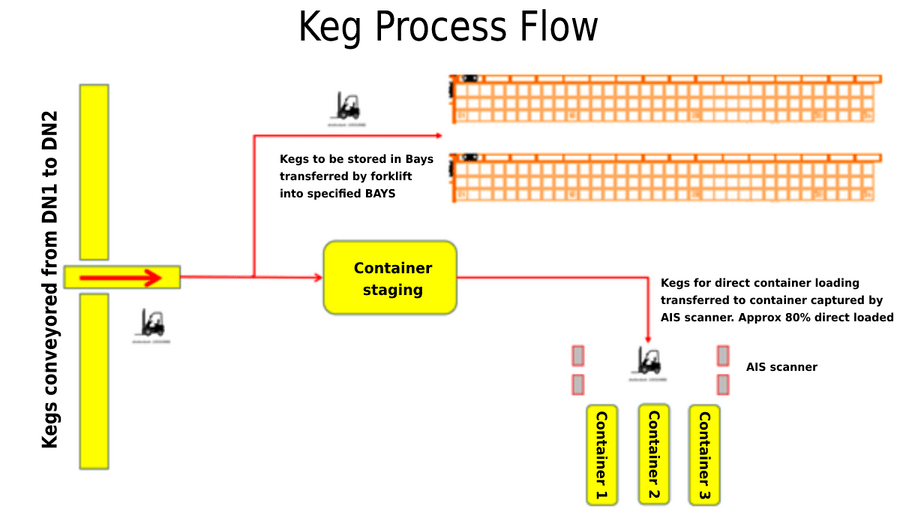

- Our team deployed a complete SAP WMS solution into the Export Warehouse operations and integrated it with the AIS Scanning system with the new WM IDoc concept breaking the complex idea of proxy programs being used earlier.

- Supported the complete Warehouse operations/material movements and the reporting needs as required by Warehouse Managers.

- Majorly reduced manual processing and dual keying of the orders and maximized the picking accuracy helping the Forklift operators to load efficiently.

- Automation of Goods receipt from Scanning to support direct load into containers with ease and business operations can continue even when the AIS system is down.

The Benefits

- Increased efficiency by 80 % of Consignment loading for Export shipments.

- Mandatory replacement of existing Warehouse system in support of ongoing £40m business.

- Reduction of Dual Keying of orders from SAP into Export Warehouse & of loads dispatched from Oracle TMS back into SAP.

- Automation of Goods receipts from Scanning to Support direct Loading, in addition to resolving existing Load scanning issues.

- Reduction of too much manual processing and dual keying in warehouse operations & increased pick accuracy via same