Manufacturing

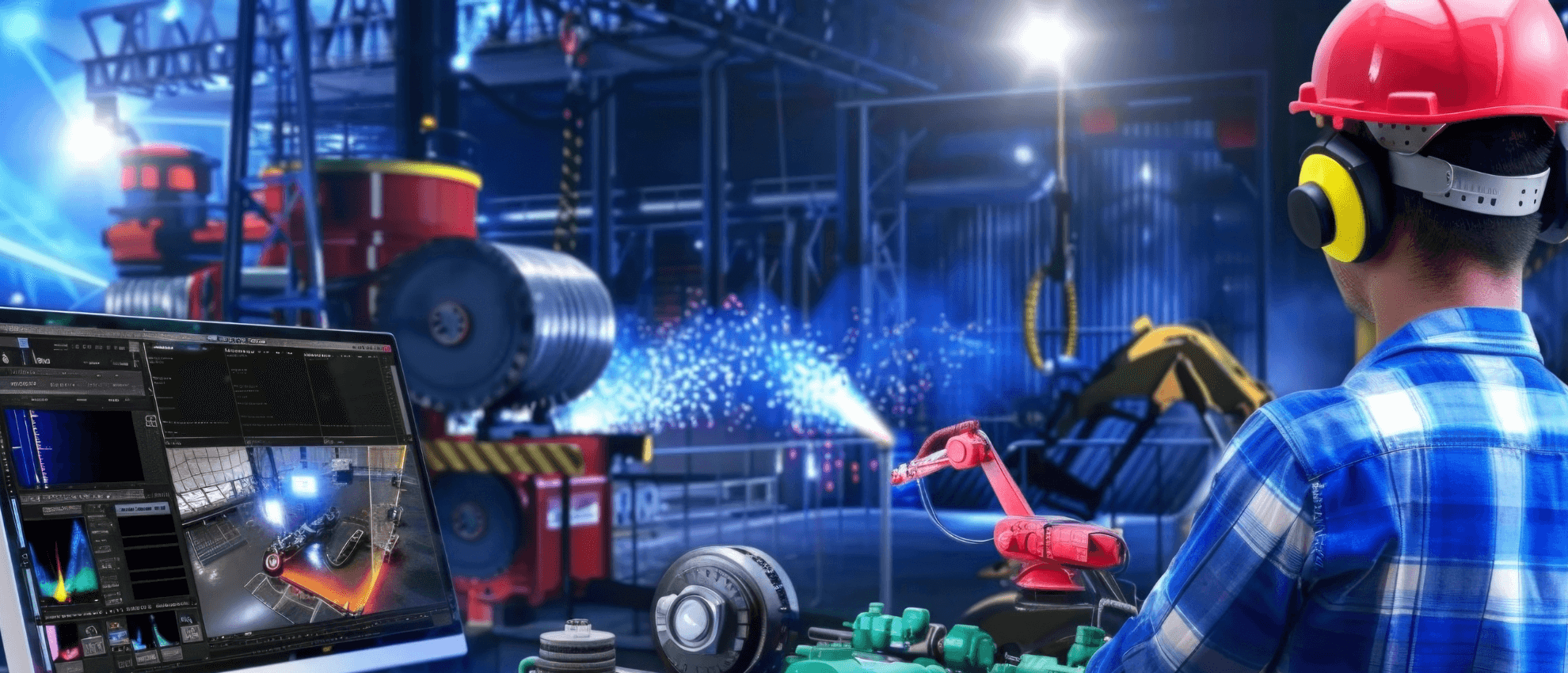

Engineering the Future of Manufacturing with Intelligent, Connected Operations

Modern manufacturing is experiencing a seismic shift. Rising costs, unpredictable supply chains, outdated systems, and stricter compliance rules are forcing manufacturers to rethink their processes.

At JK Tech, we help manufacturers transition from reactive, isolated operations to connected, predictive, and autonomous systems. Our solutions combine industry experience with the latest technology. They help factories operate smarter, faster, and more sustainably.

Optimizing Every Stage of the Manufacturing Value Chain

From shop-floor automation to smart supply chains, JK Tech adds value at every level of operation:

Predictive Maintenance & Asset Intelligence with JIVA

JIVA leverages Gen AI-driven predictive models to anticipate equipment failures before they occur, enabling proactive maintenance, reduced downtime, and optimized asset performance. With autonomous monitoring and real-time decisioning, factories gain more reliable equipment, higher throughput, and improved operational continuity.

Quality Intelligence & Defect Prevention powered by Gen AI

With Gen AI and computer vision technologies, JIVA provides the capability to identify defects at the earliest point in the production process. Gen AI improves the yield of the final product, minimizes scrap, improves compliance with government regulations, and maintains consistent product quality through automatic quality decision making and rapid identification of the root cause of defects.

Cloud-First Modernization & Data Fabric

Develop new scalable technology architectures from legacy systems that bring together operational technology (OT), information technology (IT), and enterprise systems to accelerate innovation and transformation.

Supply Chain Optimization & Planning

Create a view of the entire supply chain from suppliers through logistics and inventory; this visibility will allow you to eliminate waste, raise service levels, and bring greater resilience to the supply chain.

Digital Twin & Simulation

Use digital twins to simulate production processes for capacity planning, workflow design, and engineering decisions while reducing trial-and-error with physical prototypes.

Smart Connected Factories & IoT Integration

Integrate machines, systems, and data streams to maximize visibility into the entire manufacturing process, providing insight to make informed decisions about production operations in real time.

Why JK Tech- Your Partner in Modern Manufacturing

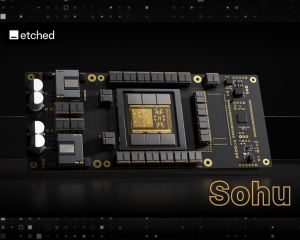

Accelerated AI-Enabled Operations with JK Tech JIVA

JIVA embeds predictive intelligence across manufacturing systems and enables rapid rollout through proven automation accelerators and factory-ready frameworks.

Outcome-Driven Innovation

Delivering measurable gains in efficiency, cost, and scalability

Deep Industry Knowledge

Decades of experience across global manufacturing environments

Composable Digital Architecture

Built to scale with flexible interoperable platforms

Discover how digital-first manufacturing works

Connect with JK Tech to get started and see what intelligent manufacturing looks like in action.

Contact UsResource Library

- Blog

- Success Story

- WhitePaper